Composite Materials

After a first observation they were “re-discovered” at the

beginning of the 90s and immediately started to cover a fundamental role in

several scientific branches, from Physics to Chemistry, going through Medicine

and Biology. In the Material Science and Engineering field a large number of

studies have been conducted on carbon nanotubes, as a consequence of their

extraordinary physical, technological and mechanical properties. For what

concerns this research, they have been largely investigated as reinforcement

materials in composites. Since 1991 a large number of attempts have been

conducted, trying to exploit the outstanding potential of this carbonaceous

material, in order to improve the properties of several matrices. The most

important application is the production of polymer matrices composites (PMCs),

but in last decades an increasing number of metal matrix ones (MMCs) have been

presented and recently also ceramic matrix (CMCs) applications have been

attempted. Despite massive efforts focused on CNTs-composites, the potential of

employing this reinforcement materials has not yet been fully exploited. This

lack is substantially due to the difficulties associated with the dispersion of

entangled carbon nanotubes during processing and poor interfacial interaction

between CNTs and matrix materials. The dispersion states of the nanotubes

involve complicated phenomena, since the carbon nanotubes are produced in

bundles or bundle aggregations. The states are affected by at least two

competitive interactions: (1) the interactions of van der Waals forces, among

carbon nanotube threads, and (2) the interactions between carbon nanotube

threads and dispersion medium. The characteristics of single carbon nanotube

and of bundles of carbon nanotubes are completely different. CNTs must be

uniformly dispersed to the level of isolated tubes individually wetted by the

matrix. This is necessary in order to achieve efficient load transfer to the

reinforcement network. This also results in a more uniform stress distribution

and minimises the presence of stress concentration centres.

Because of these reasons the very first aspect of this work

has been the study of the dispersion state of nanotubes. The aim of the

experiments was not only to obtain a good dispersion and distribution of the

CNTs, but also to evaluate their dispersion grade. Indeed, due to their

nanosize and to their carbonaceous nature, few simple experimental techniques

result suitable for this purpose. In addition, the objective was also to use

dispersion techniques which do not imply the utilisation of 7 high amount of

solvents, reagents or surfactants, and so the aim was to develop a process as

simple, low costs and as environmental friendly as possible.

The second part of the work consisted in the application of

the carbon nanotubes to the production of new materials for technological

applications, with improved mechanical properties. Three composite materials

with different matrices have been designed, developed and produced: a polymer

matrix composite, a ceramic matrix and a metal matrix one.

Also in these cases the aim of the work was the tuning of

simple and possibly low costs production systems.

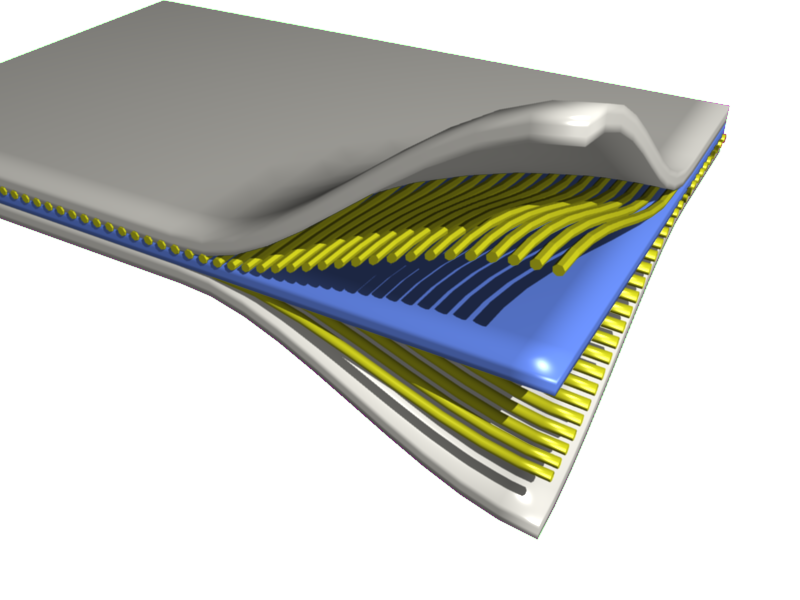

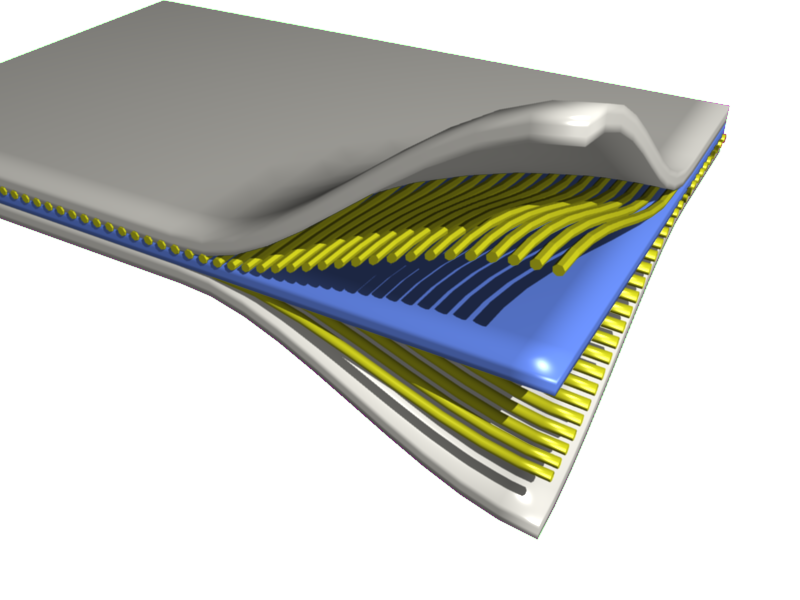

For PMCs a polyvinyl butyral matrix has been used and the

composites were obtained by a deeply studied technique in the research group:

the tape casting technology. The same approach was also used in the case of

CMCs: tape casted silicon carbide matrix composites reinforced by carbon

nanotubes have been produced. Finally a third matrix has been experimented:

MMCs were investigated starting from pure aluminium powders. For Al matrix

composites a particular technique was used: the sintering was obtained starting

from a powder metallurgy approach and exploiting electric current and pressure

(Electric Current Assisted Sintering approach).

For all the three different composite materials, after the

development of the production route and the preparation of several specimens, a

characterization step followed. The materials were characterized in terms of

physical properties, morphology and microstructure, and mechanical behaviour.

Composite materials are gaining wide spread acceptance, due

to their characteristic behavior and high strength to weight ratio. Of these

aluminium metal matrix composites are finding increased applications, because

of their improved mechanical (such as hardness, young’s modulus, yield

strength, and ultimate tensile strength due to the presence of micro-sized

reinforcement particles into matrix material), physical and tribological

properties and also the thermal conductivity of composite material are good. A

metal matrix composite (MMCs) consists of a metallic alloy matrix (such as

aluminium, magnesium, and titanium). Typically reinforced with a ceramic phase

in the form of particles, platelets, whiskers, short fibers and continuously

aligned fibers. Aluminium alloy reinforced with various particulate ceramics

particles.

Fabrication of casting is done by stir casting processes

among all the different processes.

Tungsten carbide is used as reinforcement material in

aluminium alloy as matrix.

Aluminium alloy are used in vast number of applications

mostly used in automobile filed (such as engine cylinders, drive shafts,

pistons, and brake rotors), industrial applications, aerospace applications and

it is also useful in defence applications like torpedoes, manufacture of

missile bodies, because of their low density, high strength to weight ratio,

high thermal conductivity, high elastic modulus, and good structural rigidity.

Aluminium alloy reinforced with various particulate ceramics particles are

universally known as aluminium matrix composites (AMCs).

A composite may be defined as a structural material system

that consists of two or more combined constituent’s material that are combined

at a macroscopic level and are not soluble in each other. One constituent is

called the reinforcing phase and the one in which it is embedded is called the

matrix. The bulk material forms the continuous phase that is the matrix (e.g.

metals, polymers, etc) while the other acts as the discontinuous phase that is

the reinforcements (e.g. fibers, whiskers, particulates, etc). While the

reinforcing material usually carries the major amount of load, the matrix

enable the load transfer by holding them together.

Metal matrix composites (MMCs) are important class of

material with non metallic reinforcement incorporated in metal matrices.

Aluminium (Al) alloy matrices mainly 2024, 5052, 6061, and 7071 have been

widely used as matrix materials

The present investigation has been focused on tungsten

carbide (WC) particulate composite formation by utilization of low grade

powdered graphite (Gr) by its dispersion into aluminium matrix by stir casting

method. The objective is to form the reinforcing phase within the metallic

matrix by reaction of graphite with aluminium in the metallic melt.

In this investigation aluminium 2024 (Al 2024) is the base

material and reinforced with tungsten carbide (WC) and graphite (Gr) is used

(Al 2024/WC-Graphite).

No comments:

Post a Comment